Parking Garage Inspection

Corrosion Mapping of Embedded Steel in the floor slab

This project involved assessing the condition of reinforcement steel in the floor slab of a parking garage in Toronto, Ontario, using the iCAMM inspection tool. The most interesting aspect of the project was that the slab was covered by both a thin asphaltic traffic coating and a waterproofing membrane. The presence of coatings and other material layers poses a significant challenge for conventional NDT methods (e.g., the half-cell test), however, because the operation of the iCAMM inspection tool is not impacted by surface coverings (e.g., paint, coatings, membranes, insulation, etc.), the condition of the embedded rebar could be assessed directly from the top of the floor slab.

The data collected by the iCAMM tool were used to determine the rebar cross-section loss in the inspected area. The results were well correlated with visual observations of cracking and swelling evident on the surface of the floor slab. However, slight discrepancies were also observed as expected, because the presence or the absence of exterior signs on the concrete or asphalt surface cannot always be considered as a certain representation of the actual condition of the embedded steel reinforcement.

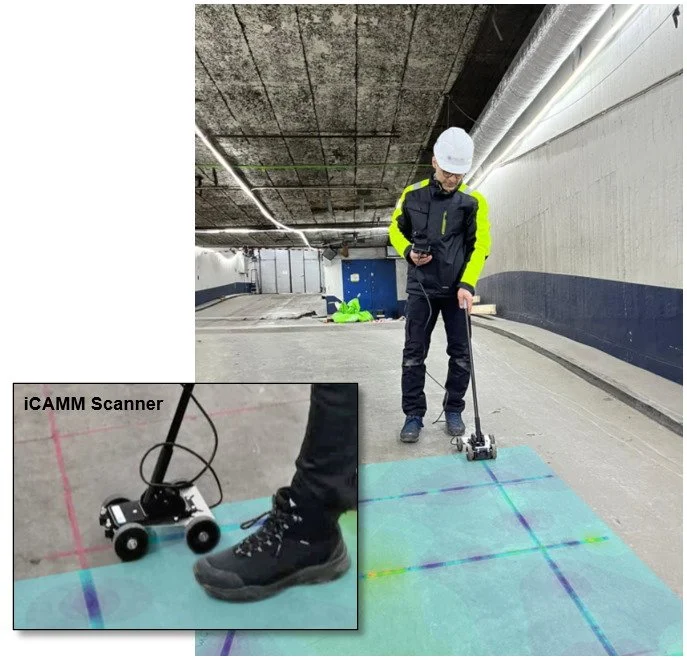

Measuring the condition of the embedded steel reinforcement in the floor slab using the iCAMM tool.

Illustration of the detailed cross-section loss results for one of the inspected bars.

Rebar Scanning in Stockholm, Sweden

This project was conducted in partnership with InspecTerra Norway and Northscan AB. The iCAMM inspection tool was used to assess the rebar condition in a parking garage in Stockholm, Sweden.

The work involved the inspection of several ramp and floor areas for corrosion, and quantifying the cross-sectional loss of steel reinforcement in all of the inspected areas. Significant variation in the degree of corrosion was found among the different areas.

This project further demonstrated iCAMM's primary advantage of allowing quantitative results to be obtained quickly and effectively directly from the concrete surface without the need for any surface preparation. The method is also not impacted by moisture or the presence of salt/chlorides, or any other adverse environmental conditions.

Download a summary of this project: