Overpass Inspection

Corrosion Mapping of Reinforced Concrete Columns

This project utilized InspecTerra’s iCAMM inspection tool for evaluating and mapping the corrosion of steel reinforcement in reinforced concrete support columns on a highway overpass in Kuwait City, Kuwait. The overpass was supported by a total of eight reinforced concrete columns. Each column was 132 cm in diameter, with the vertical steel reinforcement consisting of 22 no. 28 rebars distributed around the circumference of the column. The horizontal reinforcement consisted of spiral no. 10 rebar with a 6 cm pitch. The cover depth of the steel reinforcement was around 5 cm.

Reinforced concrete support columns for the highway overpass.

The concrete in the lower part of the columns was noticeably different from the higher sections, with visible signs of degradation such as discoloration, cracking and spalling on the concrete surface. InspecTerra’s iCAMM inspection tool can readily characterize the condition of the embedded rebar in these situations, and is not impacted by non-homogeneous properties of the concrete or any other environmental factors.

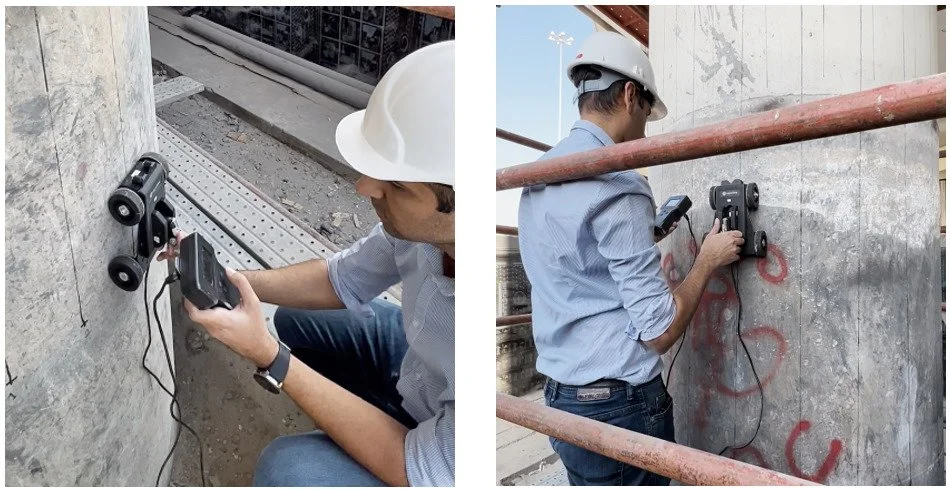

The primary vertical rebars in the lower part of each column were scanned using the iCAMM tool starting from a height of approximately 1 m. The location of the vertical rebars had been previously identified and marked by another consultant using the GPR method. The inspection of all eight columns was conducted in approximately 4 hours.

Scanning the vertical rebars using the iCAMM inspection tool.

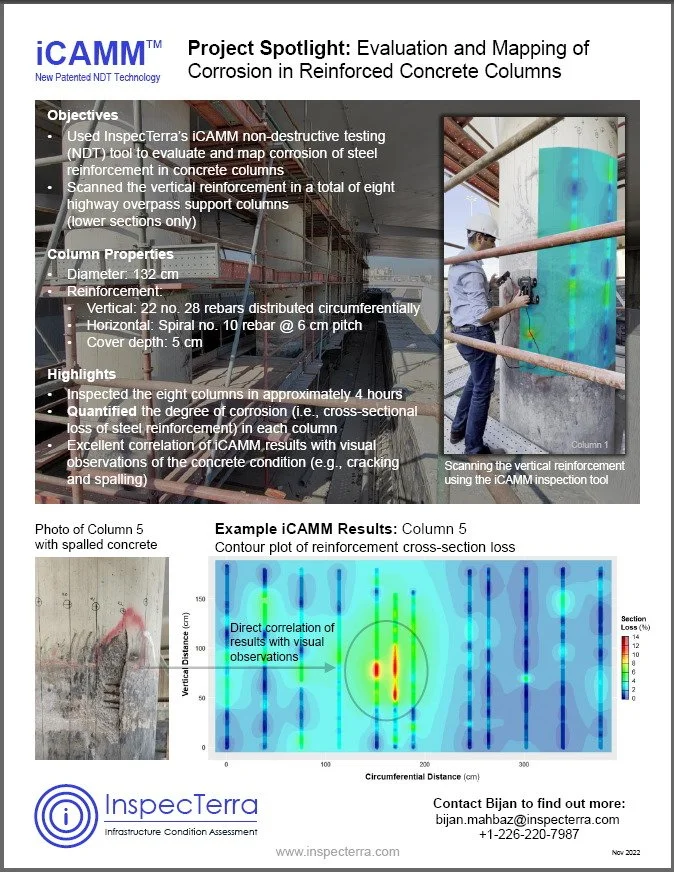

The iCAMM results were used to quantify the cross-sectional loss of the steel reinforcement in each of the inspected areas. The results were depicted as a corrosion map of the scanned area, identifying not only the location, but also the degree of corrosion of all critical areas in each column. The iCAMM results showed excellent correlation with visible signs of degradation on the concrete surface, such as cracking, disintegration, discoloration, and spalling.

Example results for Column 5, showing direct correlation with concrete spalling and rebar corrosion as measured by the iCAMM inspection tool.

This application demonstrated some of the key advantages of the iCAMM technology, which allows quantitative results to be obtained quickly and effectively without the need for any surface preparation or direct access to the embedded reinforcement.

Download a summary of this project: